Relationship Between Control Limit & Specification Limit

This article upon Relationship Control Limit Specification Limit is posted to have a better understanding for the students.

Relationship Between Control Limit & Specification Limit

Control Limits vs. Specification Limits

Control Limits are the Limits of Variation that is expected from a process when the process is said to be in statistical control. Calling a process under statistical control means all the variation in the process is resulted by Common (Random) Cause only. Such process generally shows consistency in their performance over time. Any variation that occurs outside control limits is said to be coming because of special cause. Such processes are difficult to predict for future performance. Control limit is property of process (Data). Control limit of any process signifies that all the variation from expected source falls within this limit. Generally, a very small portion of variation is only contributed by special cause, because if huge variation is contributed by a source then that source cannot be special rather that becomes common.

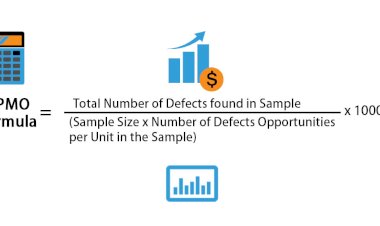

Specification limit is the limit set by customer. Generally there are two types of specification limit i.e. LSL (Lower Specification Limit) and USL (Upper Specification Limit) These limits quantify the requirement of customer (CTQ).If our product falls in the range of USL/LSL the product is said to be meeting our customer’s expectation. If our product does not fall in the range of USL/LSL, then our product is said to be not satisfying our customer need.

Specification limit and Control limits are two different measurements. As a Black Belt we might not have much control over customer’s specification but we can work on changing control limits. Again shifting or changing control limit is a time taking task. So we may have to work hard to shift/change control limit according to specification limit provided to us by our customer.

Relation between Control Limit and Specification Limit

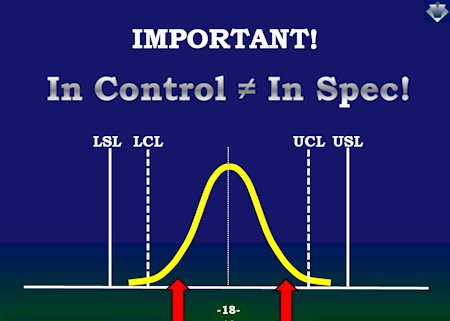

1) When Specification Limit Falls between Control Limit.

As demonstrated in the given Graph. When Control limits exceeds the specification Limit some part of the process will be functioning outside the Specification range. That Means Whenever Range of control limits is greater than range of specification limit; your process will be producing defects. Control Chart

2) When Specification Limit Coincides with Control Limit

When Control limits will fall on Specification limits, all the variation in the process which are common to the process will meet customer specification as explained in the below graph. The serious challenge in this design will be to put your system under statistical control because any variation from uncommon source will produce Defect.

Control Chart 1

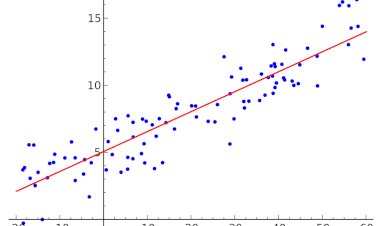

3) When Control Limit falls within Specification

This is probably the best design your process can have. In such design all the variation in your process that comes from the common source will fall in specification area. Also, Unlike Case no: 1 & 2, even if your process shifts over time (i.e., control limits of your process shifts) then it will not have severe impact on its ability to produce products/services that meets customer specification

Control Chart 2

4) When there is no intersection at all between LSL and USL

Below graph shows that the complete process is working out of specification i.e. complete process is defective. This situation appears often when your system is not at all by virtue of its design able to meet customer specification. So in such situation you need to diagnose your system. There can be only two possibilities. Either the process is performing normal but your customer’s expectation from the process is wrong or the system is not able to meet customer’s expectation by huge deficiency (Design)

control chart 3

Pankaj Kumar

Pankaj Kumar

Comments (0)

Facebook Comments