Purchasing Requirements

Purchasing procedures under ISO 9001-2008, it is ensure that purchased materials meet the requirements of the purchaser and the final customers

Purchasing procedures under ISO 9001-2008, it is ensure that purchased materials meet the requirements of the purchaser and the final customers.

Purchasing Requirements

This article is posted by Advance Innovation Group student intended to help students or depth understanding about quality management system.

The purchasing requirements in the ISO / QS 9000 standard ensure that the purchased products from different subcontractors by your organization confirm to the specified purchase requirement. The four key processes in the procurement cycle namely specification, evaluation, surveillance and acceptance should be managed effectively. The standard requires that the purchasing process from subcontractors be controlled through review. Subcontractor selection should be based on the criteria – they are assessed technically, financially and ethically. It is necessary to carry out second party audits on subcontractors to select them in the approved list. The purchasing requirement mandates the presence of documented procedures (records) of subcontractors selection. If your customer insists on verification of the subcontractors, it shall be accommodated.

For example a company let’s say named XYZ automobiles produced car parts that were used by many automobile giants. Some of the parts given by their sub contractors were not standard items. The company lacked regular performance analysis of its supplier. XXX automobiles could not quantitatively approach the quality of its suppliers and this affected their operational costs also. They found that a feedback system was needed in controlling total costs, maintaining appropriate inventory levels and delivering quality goods on time to their customers. Through the feedback, XXX wanted to highlight the performance gaps and suggest improvements to identify the black sheep amongst their suppliers. Now in this case XXX automobile decide to implement QS – 9000 quality system, provided their planning information to their suppliers in advance and gave them the additional information about they were standardizing the system.

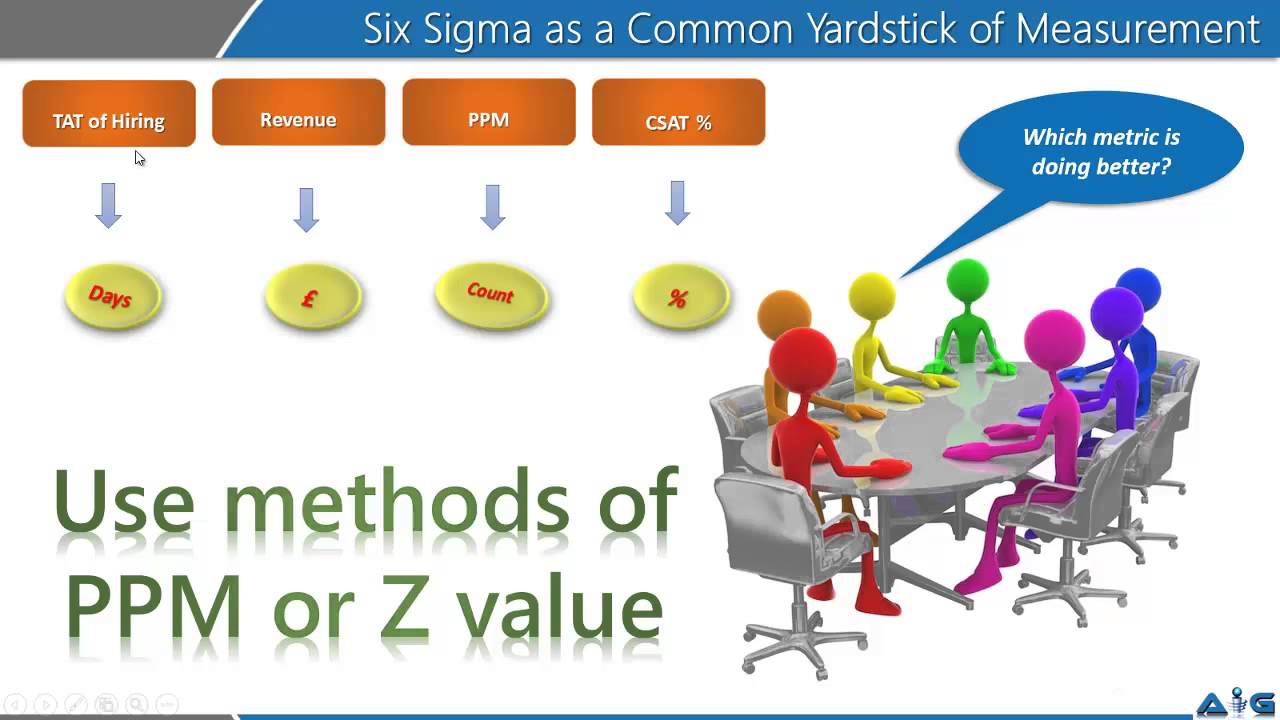

Now let’s talk and discuss about some terminology or we can say Glossary which we use in ISO 9000 (Quality Management System).

Customer – A customer is anyone who receives products or services from an organization.

Non – conformity: Non – conformity refers to a failure to comply with requirements. A requirement is a need, expectation, or obligation. It can be stated or implied by an organization, it customers, or other interested parties.

Service – According to ISO / QS 9000, a service is a type of product. Service is always the result of an activity or interaction between a service supplier or we can say service provider and a customer and can take many forms.

Supplier – A supplier is a person or an organization that provides products. Suppliers can be either internal or external to the organization.

Additionally, it is advisable that you also visit and subscribe Advance Innovation Group Blog (http://advanceinnovationgroup.com/blog) for more Lean Six Sigma Project, Case Studies on Lean Six Sigma, Lean Six Sigma Videos, Lean Six Sigma Discussions, Lean Six Sigma Jobs etc., How to start a Lean Six Sigma Project, Help on Lean Six Sigma Project etc.

Pankaj Kumar

Pankaj Kumar

Comments (0)

Facebook Comments