Control Plan

Through this article the author provides details of Control Plan - An important constituent of Lean Six Sigma projects and outside.

Through this article the author provides details of Control Plan – An important constituent of Lean Six Sigma projects and outside.

Control Plan

In most of the organizations, there exists a plethora of problems and issues affecting the business. Most of the times, organizations learn to co-exist with these problems even when they are stopping its progress. Action is only taken when the situation seems to be going out of hand. Still only temporary fixes are found and implemented which solves the problem for some time as the organizations lack the discipline needed to sustain these solutions. But very soon, the problem resurfaces and the situation returns back to its original state.

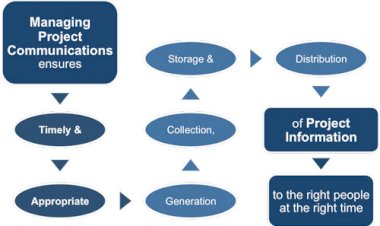

This is where Control Plan steps in. It is a tool which helps the business in sustaining solutions for problems for a long time. It is also a vital tool used in Process Improvement methodologies such as Six Sigma to sustain process improvements. Control Plans are documents, generally prepared in Excel, and consist of product and process characteristics, which are constantly monitored for any deviations. It has the monitoring mechanism for checking the process performance for any negative issues and the reactionary mechanism to deal with these deviations.

In a Six Sigma project, Control Plan is prepared generally during the Control phase. The project Leader prepares this in company with the Process Owner and with inputs from all the stakeholders and departments involved in the process.

Contents of a Control Plan

• A general description of the process

• Revision history (if applicable)

• Mention the stakeholders benefitting from the process

• Mention the stakeholders who are involved in the process in any of its steps

• Visual representation of process steps being performed

• Requirements for major steps of the process

• Measures for evaluating successful completion of major steps of the process

• Indicators for representing successful completion of these steps

• Indicate control limits for the process

• Mention Control Charts which are applicable to evaluate the process performance

• Mention the factors that need to be checked, time duration and person or department responsible for monitoring this

• Contingency plans in case the process control limits are breached or there seems to be Special Cause Variation in the process

• Mention the person responsible for these contingency plans

• Mention any other information or documents to be referred if needed.

Audit Mechanism

Apart from all these contents, a robust audit mechanism for the process must also be designed and implemented as this helps in inculcate discipline among the people working in the process. An Audit plan with an audit calendar must be formulated for auditing the process monitoring mechanism and the persons responsible to ensure that process is being correctly monitored at all times. All the deviations found in the Audits so performed must be addressed by the management to solve the issues found. Not only will it inculcate the much needed discipline in the process and organization, but it will also help the organization to fulfill its requirements, as mandated by the ISO standards.

Pankaj Kumar

Pankaj Kumar

Comments (0)

Facebook Comments