Process Engineer DC- B.E Mechanical- MNC- Nasik.

Process Engineer DC- B.E Mechanical- MNC- Nasik.

Process Engineer DC- B.E Mechanical- MNC- Nasik.

url to apply- https://www.naukri.com/job-listings-process-engineer-dc-b-e-mechanical-mnc-nasik-uni-eservices-hr-solutions-pvt-ltd-nasik-5-to-7-years-070121002392?src=sortby&sid=16132208327572041_1&xp=5&px=1

Process Engineer DC- B.E Mechanical- MNC- Nasik.

UNI-eServices HR Solutions Pvt. Ltd

Hiring for MNC

5 - 7 years

₹ 4,00,000 - 6,00,000 P.A.

Job description

We have opening with leading MNC client for Nashik location -

Interested candidates can mail your resume at unihr02@gmail.com

Roles and Responsibilities

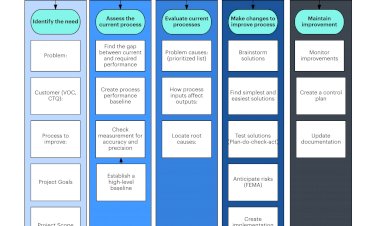

- Review, modify and evaluate the existing process design. Use this knowledge for performing process qualifications at defined frequency.

- Develop jigs, fixtures, tools and measurement facilities for New Process, productivity Improvement and Process Improvement.

- Identify and visit to suppliers for development of machines, Jig/Fixtures, measurement facilities and tools.

- Implement corrective & preventive actions based on customer complaints, feedback, and internal inputs.

- Plan, upgrade and Reconditioning of existing machines.

- Prepare, review and maintain process FMEA and production control plan for manufacturing lines.

- Prepare, review, and release operating procedures for processes.

- Prepare, review, and release manufacturing cautions.

- Plan, improve, and stabilize process capability.

- Customer complaints: Taking corrective actions (necessary changes in processes) based on QA analysis and evaluate the result.

- Identify, plan and execute cost reduction projects/Process Improvement Projects/ Safety related projects as per budget.

- Taking corrective and preventive action (necessary changes in processes) based on QA analysis and evaluation of NC product.

- Plan, prepare, review and establish shop floor layouts for manufacturing lines.

Desired Skill Sets

- Industrial engineer who knows about line balancing

- Process qualification & requalification

- Hands on experience on PFMEA & Control plan

- Knowledge of capacity calculation

- Excellent in project management

- Knowledge of Process capability & process behavior

- Understand Automation PLC Controls , communication protocols

- Excellent in time study & process mapping

- Understanding IATF requirements

Desired Outcome

- Cost reduction

- Customer satisfaction

- Defect free Product

- Process Simplification / Productivity improvement

Education B.E in Mechanical Engineering

Experience 5 to 7 years of relevant experience (Experience in mass manufacturing Company)

Skills

- Skilled in AutoCAD and Solid Edge

- Able to execute automation projects

- Able to make FMEA, Control Plan, Work instructions

- Skilled in using SAP System

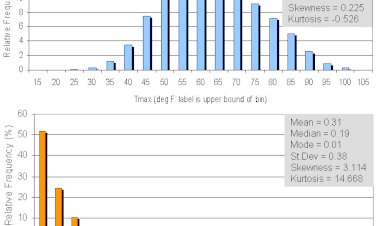

- Knowledge of Six Sigma or SPC

- Good Communication Skills

- Analytical Skills

- Handling different audits like internal audits, customer

- Audits by certification bodies.

Knowledge

- Electrical / electronic / Automotive Mfg

- TPM exposure (KK / DM Pillar)

- IATF 16949 - 8D

RoleQuality Assurance/Quality Control Executive

Industry TypeElectricals, Switchgears

Functional AreaProduction, Manufacturing, Maintenance

Employment TypeFull Time, Permanent

Role CategoryProduction/Manufacturing/Maintenance

Education

UG :B.Tech/B.E. in Mechanical

Key Skills

TPMprocessFEMASAPQA AnalysisAuto CaddProcess EngineeringJigs fixturesB.E MechanicalProcess engineer DC

Pranay Kumar

Pranay Kumar

Comments (0)

Facebook Comments