Assistant Manager - CIC

Assistant Manager - CIC

Assistant Manager - CIC

url to apply- https://www.naukri.com/job-listings-assistant-manager-cic-acg-associated-capsules-pvt-ltd-dahanu-7-to-9-years-180221003301?src=sortby&sid=16139011163456589_1&xp=9&px=1

ACG Associated Capsules Pvt Ltd3.9(113 Reviews)

7 - 9 years

₹ 60,000 - 70,000 P.A.

Job description

Continuous Improvement Team Member - Plant

- Organization Context

Position Title:CIC Assistant ManagerEmployee Name: Grade :M6Department:CICLocation:DahanuReports to:Plant CIC ManagerReported by:-

- Job Objective

- Deliver Continuous Improvement projects through structured analysis and evaluation of to improve plant performance metrics

- Provide support to project leaders in creating project plans, analytics, conducting observation studies, develop control plans to ensure on time project delivery.

•

- Design and implement change management events inline with CI roadmap

- Support in driving the technical and analytical capability building for the plant in order to achieve operational excellence

- Primary responsibilities

Strategic and planning

- Support the Plant CI manager in execution of CI strategy

- Identify Improvement areas and plan improvement projects and CI initiatives for the plant

- Create an assessment structure to measure the effectiveness of CI initiatives vis-a-vis the envisaged project outcome

- Plan & Align resources (reading modules) for technical trainings and provide support as needed

Functional

Core

- Facilitate cross functional focussed Improvement projects using Lean and Six Sigma complex problem-solving methodology.

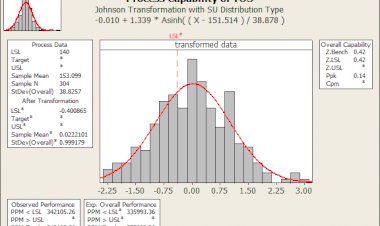

- Analyse Continuous Improvement project data using Six Sigma statistical tools and conduct Gemba observation studies for cause validation and improvement actions.

- Facilitate and develop detailed project plans along with project leaders for Lean and Six Sigma improvement projects

- Coordinate and follow up for action plans and ensure on time delivery of CI projects

- Monitor daily project wise actionable/observation studies/trials and the project participation of the stakeholders through various systemic methods

- Monitor and communicate project status periodically to all stakeholders

- Facilitate Small Group Activity (Quality Circle) teams for Problem Solving.

- Facilitate implementation of Kaizen to drive small improvements across the plant

- Conduct Value Stream Mapping, Bottleneck Process studies for Improvements

- Creation of training module for various CI skill sets (Lean, Six Sigma, Kaizen, TPM)

- Plan and Execute Six Sigma, Lean, Kaizen, TPM trainings.

- Execute and support in imparting Technical Trainings as per training Calendar

Internal process

- Facilitate weekly Project Reviews with Plant Project team, Plant CIC Manager, Plant Head and Functional CIC Head

- Facilitate monthly Plant Steering committee reviews

- Escalate delays, challenges and non-compliances in implementing various CI initiatives to Plant CI Manager and Plant Head.

- Create CI Projects Dashboard for Review by Plant Head and Top management

- Conduct GEMBA walks with HODs to regularly identify potential areas of improvements and track the implementation of the same.

- Conduct Gemba Kaizen Idea Workshops and Kaizen initiatives across the plant

- Collaborate with all relevant stakeholders in executing, monitoring and tracking of Technical Training

People development

- Train the people across all departments on Gemba Kaizens to develop CI culture.

- Support in design and execution of Quarterly Kaizen Events, yearly Six Sigma Project competitions for employees.

- Identify & develop project teams for analytics and sustenance of improvements

- Key Result Areas

- No. of high impact Continuous Improvement Projects completed vs planned (*provided this is reflected in the respective JD of Plant Head & Function Head)

- No. of Kaizen and Quality Circle Projects Completed vs planned

- No of processes standardized through various CI projects

- No. of People Trained in CI tools and technique, technical skill set against planned

- Compliance to Kaizen Idea Workshops & Events as per Plan

- GEMBA Walks Improvements Planned vs Actuals

- Overall competency enhancement level of associates Planned vs Actual

- Key Interfaces

Internal InterfacesExternal Interfaces

- Production

- Quality

- One Engineering

- Post Manufacturing (PFD)

- HR

- Central CIC

- Project Steering Committee Stake Holders

- External Consultants

- External Vendors

- Competency

Technical Competency T CompassLeadership Competency – L CompassCompetencyLevelCompetencyLevel Problem Solving KnowledgeAdvancedCross Functional Team WorkAdvancedSix Sigma KnowledgeAdvancedCommunicationAdvancedKnowledge of Minitab & Statistical ToolsIntermediateResult OrientationIntermediateLean ManagementIntermediateQuality and Service OrientationIntermediateTPM KnowledgeIntermediateInnovationIntermediateMicrosoft OfficeIntermediateCorporate EtiquetteIntermediate

- Educational and Experience Requirements

Minimum Requirement Desired Level of Education

- BE/B-Tech

MBA OperationExperience

- 8-10 years

Must Be

- Lean Six Sigma GB/BB Certified

Six Sigma BB CertifiedIndustry

- Manufacturing Industry

Automobile, FMCG and Pharma manufacturingFunctional Expertise

- Continuous Improvement,

- Manufacturing Excellence,

- Operational Excellence

World class Manufacturing,

Business Excellence

Prepared ByMahesh ThakurDate1st Jan 2021SignatureReviewed By Date Signature

RoleAssistant Manager/Manager-(NonTechnical)

Industry TypePharma, Biotech, Clinical Research

Functional AreaITES, BPO, KPO, LPO, Customer Service, Operations

Employment TypeFull Time, Permanent

Role CategoryBack Office/Web/Transaction Processing

Education

UG :B.Tech/B.E. in Any Specialization

PG :MBA/PGDM in Any Specialization, M.Tech in Any Specialization

Key Skills

Operational ExcellenceContinuous ImprovementLean Six Sigma

TPMChange ManagementTop ManagementGemba KaizenTechnical TrainingOperationsValue Stream Mapping

Pranay Kumar

Pranay Kumar

Comments (0)

Facebook Comments