Story Behind Six Sigma Method

Story Behind Six Sigma Method

Story Behind Six Sigma Method

Story Behind Six Sigma

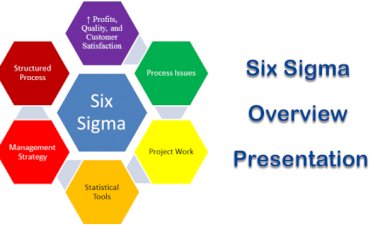

In 1986, engineer Bill Smith of the Motorola Corporation introduced the now wildly popular Six Sigma approach. It is a business management strategy with the stated, understood the goal of reducing the amount of defects in production to a minor level. The idea for Six Sigma was the conclusion of other quality control innovations up to that point in history, and combines what at the time had been recognized to be the most actual and competent parts of different quality control initiatives. One of the next steps, was the statement that all aspects of creation, even output quality, could be converted to quantifiable and measurable data. This leads to the assumption that manufacturers have complete control over the quality of process output. Also essential part of Six Sigma is the highlighting on combined efforts and teamwork. It is specifically stated that quality improvement needsdevotion and assurance from staff at all levels. Motorola itself was also the first multinational corporation to implement this advantage.

Appropriating a concept from Eastern martial arts, practitioners of Six Sigma are ranked by “belts.” Different belt colours specify different roles and responsibilities. For initial level, Green Belts are the lowest rank, and are responsible for operation in their division, along with other workplace commitments. Green Belts operate under the supervision of Black Belts, the next rank up. Black belt primary attention is on the implementation of projects. The next rank, Master Black Belts, are more approximately responsible for the general, company-wide implementation of this method, as well as acting as a supporter for Six Sigma Black Belts and Six Sigma Green Belts. The last rank is Champion, who supervises all practices within the scope of thetotal enterprise. Champions also assist to guide all lower-ranking Belts.

Whether it’s collecting data, implementing changes, or forming a vision for the prospect, experts of Six Sigma are and this initiative itself, is one of the most proficient means of quality control and process management available. It is the most tested and dependable way we have for accomplishing stable and maintainable business processes. Widely regarded as the standard of quality that all corporate entities should strive to achieve, Six Sigma has modernized the fields of quality control and process management.

Pankaj Kumar

Pankaj Kumar

Comments (0)

Facebook Comments