Quality Enginner

Quality Enginner

Quality Enginner

url to apply- https://www.timesjobs.com/job-detail/quality-enginner-commscope-3-to-5-yrs-jobid-LGhVwh28CcFzpSvf__PLUS__uAgZw==&source=srp

COMMSCOPE

- card_travel3 to 5 yrs

- ₹As per Industry Standards

- location_onUnited States of America (USA) (United States Of America (usa))

JOB DESCRIPTION

This Quality Engineer will be an member of the CommScope Global Quality & Reliability organization supporting the BSA business units in Suzhou, China. Primary responsibilities include BSA PDP design/process FMEA, SPC, ECR Quality Control Plan through product design and new product introduction.

SPECIFIC DUTIES AND RESPONSIBILITIES:

Provide oversight for overall PDP adherence, raise flags as appropriate

Lead the project DFMEA review from material, sub-assembly and antenna level, to identify the design risk in advance, as quality perspective, follow up the issues to be solved with root cause identified.

Launch New Product Develop D/PFMEA into Relyence FMEA tool database

Develop the project CTQ from material, assembly, test, and transfer to NPI and Ops.

Review and escalate issued related to design from NPI, test, operation and customer, lead the RCA analysis and solutions, notice extended plants about material and antenna disposition

Ensuring that lessons learned are gathered and are feed back into new development activities.

Make sure PDP and related global procedure implement during the whole design phase, monitor and audit the released projects, identify key gaps and develop/upgrade PDP processes by working with key stakeholders to meet and adapt to the current market environment.

Communicate to cross team any opportunity for design and quality optimization as quality matter.

Provide the necessary internal and external training to design and related team about obligatory procedure and requirements.

Identify the currently procedure and process gaps from the roll out experience, define the actions to improve process value and effect.

Initiate and define the new procedure and flow chart to meet new design environments.

As design quality perspective, use the exactly tool to improve and prove the design performance and stability, as CPK, D/PFMEA, WI, SPC, RCA, CP, CTQ, lesson learned, gate reviews, DFM/A, Design standards (RF & ME & Electronics).

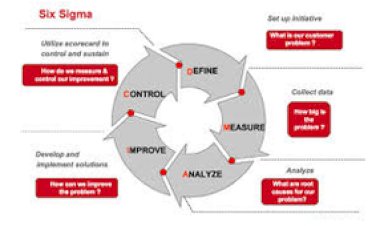

Lead the DMAIC project with crossed team to drive continuous improvement in the design and to Materials, Processes, Products.

Support Ops team and other plant feedbacks on any design improvement and optimization.

POSITION/TRAINING REQUIREMENTS:

Minimum of a Bachelors Degree in Engineering or a related Technical field.

Working knowledge of basic and advanced Quality tools such as TQM, Six Sigma, SPC data analysis skills, FMEA, Control Plans, 8Ds, Root Cause Analysis, Poka Yoke, etc.

Working knowledge of ISO 9001/TL9000 Quality Management System Standards.

3-5 years or more of previous Quality experience, preferably within a design and Lean environment.

6 sigma green belt certification requirement as preference, timerpro and continue improvement IE tool/skills are strong desired.

Ability to work effectively with all cross functional areas and across international/cultural boundaries.

The ability to work in a team environment and a high level of self-motivation and drive for improvement

Strong self-study ability, willing to learn and accept new skills which are needed in working.

Excellent communication and interpersonal plus presentation skills.

Must be fluent in Mandarin Chinese and proficient in English

- JOB FUNCTION:Quality/Process Control

- INDUSTRY:Telecom, Manufacturing/Industrial

- SPECIALIZATION:Quality Assurance

- QUALIFICATION:

- ME/ M.Tech./ MS (Engg/ Sciences)

- Any Graduate

- EMPLOYMENT TYPE:Full Time

KEY SKILLS

six sigmanew developmentlean six sigmapfmeaquality engineergreen beltfmeaiso 9001cpkctqquality controlquality managerprocess fmeadmaicspcquality managementquality tools

Pranay Kumar

Pranay Kumar

Comments (0)

Facebook Comments