Supplier Quality Engineer

Supplier Quality Engineer

Supplier Quality Engineer

url to apply- https://www.timesjobs.com/job-detail/supplier-quality-engineer-emerson-electric-co-india-pvt-ltd-china-5-to-8-yrs-jobid-pwr1M507qhFzpSvf__PLUS__uAgZw==&source=srp

Emerson Electric Co India Pvt Ltd

- card_travel5 to 8 yrs

- ₹As per Industry Standards

- location_onChina (China)

JOB DESCRIPTION

1. Develop suppliers for PPM monitoring, any NCR issued with preventive actions implemented 20 PERCENT

(1) Train suppliers to effectively execute Supplier Corrective Action Requests (SCAR), ensure complete & effective root cause analysis and Corrective Actions Preventive Actions (CAPA)

(2) PPM reduction to meet team target

2. Conduct regular Supplier Quality system and process audit for team requested 15 PERCENT

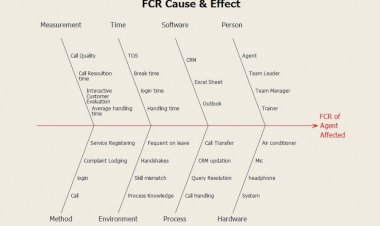

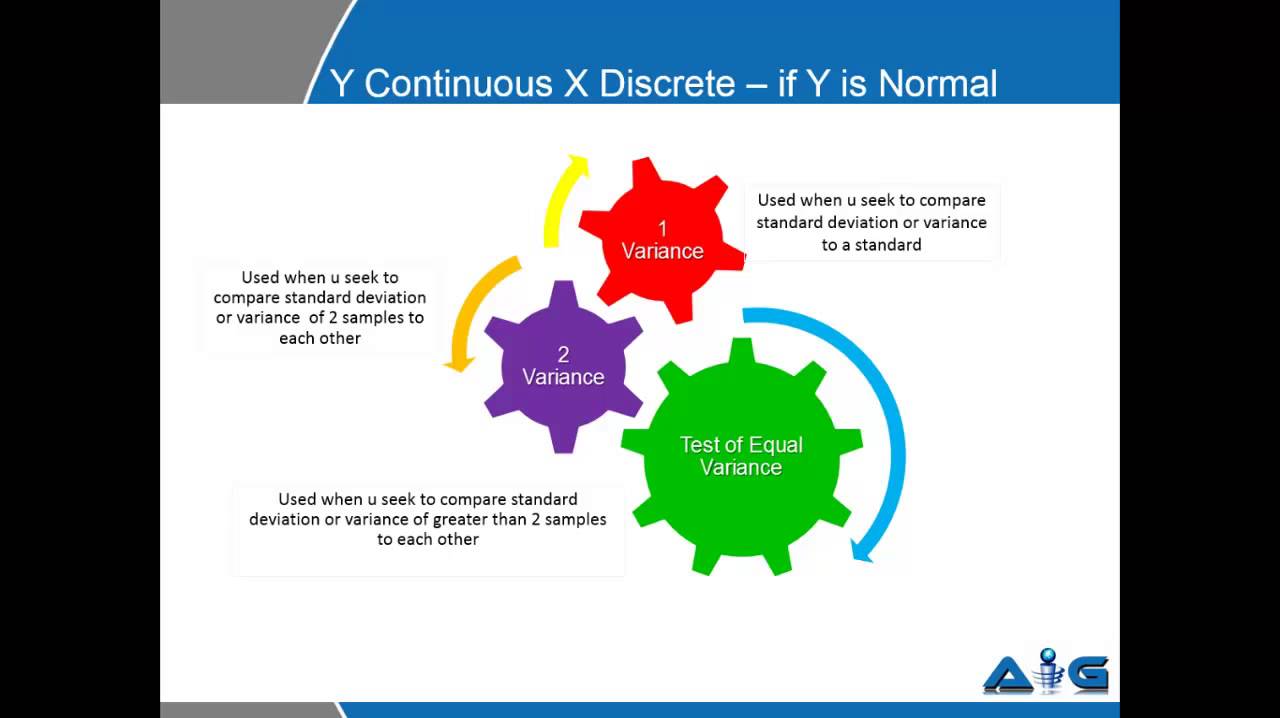

(1) Use the statistical Process Control (SPC), Advanced Quality Process (AQP) tools to proactively identify and help implement improvement to the Supplier Quality and Supplier Quality tools and Processes.

(2) Regular Quality system audit for obligated suppliers and process improvement by audit in critical suppliers for critical parts

(3) New supplier qualification, work with sourcing department on supplier background review, factory audit and samples approval

3. Focus on China Supplier development for preferred suppliers by quality development and delivery on time 30 PERCENT

(1) Set up 1~2 projects in prefer supplier by yearly on supplier KPIs, and try to close them in fiscal year

(2) Regular review projects with team and supplier to adjust the destination if necessary

4. Monitor FA projects and push samples submission on time performance 20 PERCENT

(1) Involve project at the initial launch stage, review the drawing and host project launch meeting in Supplier to clear every critical request are concerned and design related preventive action

(2) Work close between FA inspection lab in AP, purchasing sites and suppliers to make sure FA inspection result is acknowledged.

(3) Follow FA schedule by Supplier scheme, review every changed time nodes with supplier and report to new project development team if necessary.

5. Technical support for commodity team and suppliers 15 PERCENT

(1) Work closely with Sourcing team to establish and maintain a Supplier Quality Scorecard which includes Delivery, Cost, Partnership

Requirements

1. Over 5 years working experience with at least 3 years in supplier quality management

2. Bachelor degree or above in Engineering/mechanical/electromechanical

3. Good communication with persuasion skills, Fluent English reading and writing, Work Independently.

4. Able to communicate with CEO from suppliers

5. Good problem solving skills, strong project management skills, Strong Adaptability

6. Auditor experience

7. Must be a critical thinker and active listener with good time management skills in order to work with suppliers and project management teams to define deliverables

Preferred:

Working on supplier control experience with Machining, Stamping, Casting parts, Plastic injection will be an advantage.

Be good at how to use all inspection instruments, such as calipers, micrometer, microscope, CMM, projector and contracer.

Lean six sigma training (Certification preferred)

- JOB FUNCTION:Production/Manufacturing/Maintenance/Packaging

- INDUSTRY:Manufacturing/Industrial

- SPECIALIZATION:QA/QC

- QUALIFICATION:

- Any Graduate

- EMPLOYMENT TYPE:Full Time

KEY SKILLS

supplier developmentsupplierslean six sigmainspectionppm monitoringspcstatistical process controlquality assurancecmmfood qualitymicrometerprocess auditsupplier quality managementcapappmsupplier quality

Pranay Kumar

Pranay Kumar

Comments (0)

Facebook Comments