Cp and Cpk

Cp Cpk Process Capability indices are very common in Six Sigma Projects and outside. They form the preliminary measure of Process Performance

Cp Cpk Process Capability indices are very common in Six Sigma Projects and outside. They form the preliminary measure of Process Performance

Cp and Cpk

Cp Cpk are Process Capability Indices which are very commonly used in Lean Six Sigma projects and outside.

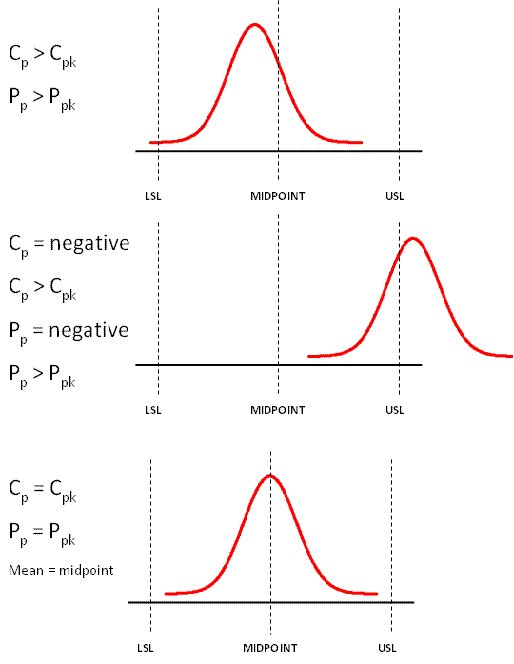

Cp is based on normal distribution that means the upper specification limit (USL) is the upper limit of the specified range. Similarly the lower specification limit (LSL) is the lower limit of the specified range. See: Specifications. Standard Deviation. The standard deviation is a measure of variability in a process.

The calculation of Cp=USL-LSL/6stdev

Cp as the inherent process capability is a measure of the design ability of your process and it reflects the true “ability” of the system at hand.

Cpk is indices for measurement of process capability and Cpk is measure of Potential process capability

i.e. how well your process can perform under best conditions. The Calculation of

Cpk = minimum of (Cpu , Cpl) or minimum of (Cpu=( USL-Mean)/3 stdev , (Mean- LSL)/3 stdev)

Pankaj Kumar

Pankaj Kumar

Comments (0)

Facebook Comments