Exploring Linkage between FMEA, SPC, Control Plan and CAPA

Exploring Linkage FMEA, SPC, Control Plan CAPA is very important when one would want to make a robust process plan for any process.

Exploring Linkage FMEA, SPC, Control Plan CAPA is very important when one would want to make a robust process plan for any process.

Exploring Linkage between FMEA, SPC, Control Plan and CAPA

It is often said that FMEA (Failure Modes and Effects Analysis) and SPC (Statistical Control Plan) should be used in business processes so it is very important activity of Exploring Linkage between FMEA, SPC, Control Plan and CAPA. Along with many management gurus, the TS 16949 and Six Sigma also say the same thing. But it is easier said than done as one learns it from their own experience or say failures about how to link FMEA with SPC and Control Plan.

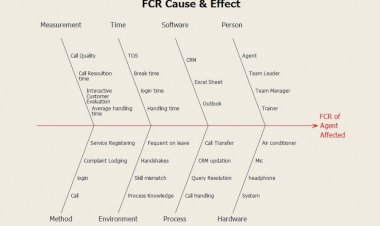

Let us understand how to establish the link between these. The start of any process improvement project is initiated with drawing the process map. Somewhere along the way, a FMEA for the process is also prepared. The Risk Priority Numbers (RPN) for the various risks are calculated and allocated as per the inputs of the project team. Either all the risks are taken for action or are prioritized as per the RPN values. Either way, a Risk Treatment Plan (RTP) measures are decided to minimize or eliminate the risks. Responsibility is allocated for these measures and action details are taken from the responsible persons for these measures. RPN is again calculated to see how much the given risk has been controlled or eliminated.

Now action shifts to the Control phase. A Control Plan is prepared and the measures identified in the preparation of FMEA are taken as inputs for controlling the risks. Responsibilities are allocated and time periods are fixed to monitor these measures. The responsible persons have to be given instructions and training for completing this monitoring task for which SOPs (Standard Operating Procedures), WI (Work Instructions) and/or Training Manuals are prepared. Training is given to these persons accordingly.

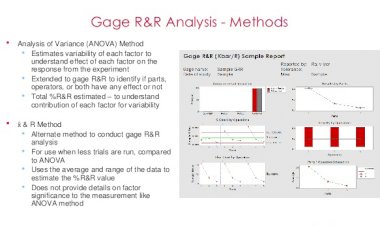

Now this monitoring has to be done through some measurement system for which a SPC study will be required. The type of Control Charts required and other measurement criteria/system has to be mentioned in the Control Plan along with the time duration required. Audit plans are mentioned to constantly monitor the process performance to all the stakeholders and Process Owner. Finally, contingency plans or reaction mechanism are formulated to decide upon the corrective action to be taken whenever the process is going out of control or showing some special cause variation. These contingency plans give detailed instructions about what action has to be taken whenever the process reported to have failed. In certain cases where the process had failed and no mention was made about this failure mode either in FMEA or Control Plan, then after taking corrective action both would have to be updated for the same.

Hence, in this way, FMEA is linked to the Control Plan while the Audit Plans, Contingency Plans and Reaction Plans help the organization to have a structure and fulfill its obligations to the QMS under the Corrective Action and Preventive Action requirements of the ISO standards.

Pankaj Kumar

Pankaj Kumar

Comments (0)

Facebook Comments