Process Capability Calculation

This article on Process Capability Calculation shall help the reader understand the concepts around Process Capability and the related calculations.

This article on Process Capability Calculation shall help the reader understand the concepts around Process Capability and the related calculations.

Process Capability Calculation

DPMO :

DPMO means Defect Per Million Opportunities. DPMO concept is widely used in Six Sigma to know a process is producing how many defects for every million opportunities. Any steps in a production or service provided there is a non-conformity with a pre-decided specification or acceptance value is a defect. DPMO is the criteria to judge the health of a project to know how many defects are being captured for every million opportunity

Let us take an example:

If in a road 1 km long, speed is being captured for 4 vehicle types for every meter of road.

Total length of road = 1000 m

Opportunity per meter = 1 meter * no of vehicles = 1*1 =4

Total opportunities = total road length * no of opportunity per meter = 1000*4 =4000

Total defects found = 200

DPMO is calculated by dividing the no of opportunities multiplied by 1 million

DPMO=Total Defects divided by Total Opportunities multiplied by 1 million

Here DPMO = 200/4000*1000000

= 50000 defects per million opportunities.

Zee score

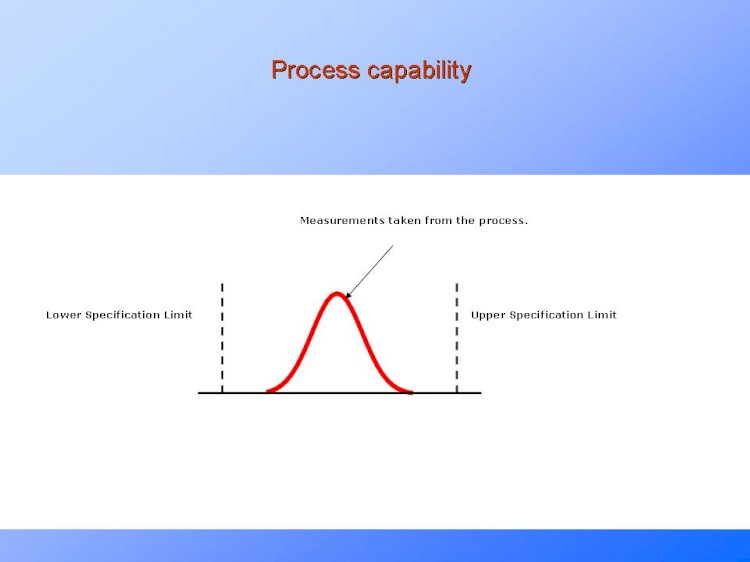

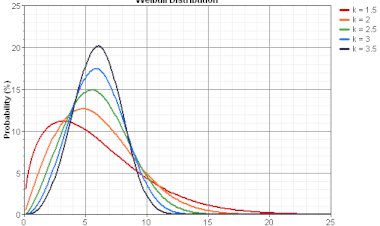

Zee score is commonly called as sigma level of quality. It is the no of SD that lies between the specification limits. Let us explain it in detail.

In a process, its center is generally represented by its mean. And the variation in the process is represented by the No of Standard Deviation that fits in between. Ideally, 3 SD are there on both sides of the Mean. But taking into consideration the specification limits(provided either by the customer, or some standard or anything else) any values lying outside the specs are the defects that are affecting the process. It is generally found that a low zee score means that the count of defects are high. This means that a high zee score means that the process is in good health.

Zee score is calculated in 2 ways. In the first, short-term score is calculated by taking short term SD. Whatever figure that comes out is the Zee Short Term score.

But the catch here is that what type of SD are we taking into consideration as SD can be both short-term and long-term. Inc case Short term sigma score is being calculated then 1.5 sigma is added to the short term process.

Cp and Cpk

Cp – Cp is the process performance given in the process design. It means that it is the performance of the process that is decided when the process is being designed. Cp in simple terms means Process Capability.

Cp = USL-LSL/6SD

As a result of this formula; Cp value is got in 3 manners:

Cp < 1. In this case, it means that the Process Capability is not performing as per expectations and a lot of defects are occurring. This means that the process requires close monitoring and steps should be taken to restore its health.

Cp = 1. This is the ideal state where process performance fits exactly between the specification limits. But the danger here is that there is no room to maneuver and the process has to perform at this level all the time. There is no margin for error and even a small deviation will result in defects

Cp > 1. This means that the process is performing very well and is present well within the specification limits.

Cpk

Cpk is the Process Performance Index. It measures the actual performance of the process in relation to the specification limits and the variation found. It is calculated by first calculating capability of upper side from Mean (Cpu) and capability of lower side from Mean (Cpl). The minimum of both is taken as the final Cpk

Cpk USL = (USL-Mean)/3Sd Cpk LSL = (Mean-LSL)/3 Sd

The minimum of both values is taken as the Cpk.

Pankaj Kumar

Pankaj Kumar

Comments (0)

Facebook Comments