How important Improve phase is in a Six Sigma project?

Improve Phase of a Six Sigma Project

Improve Phase of a Six Sigma Project

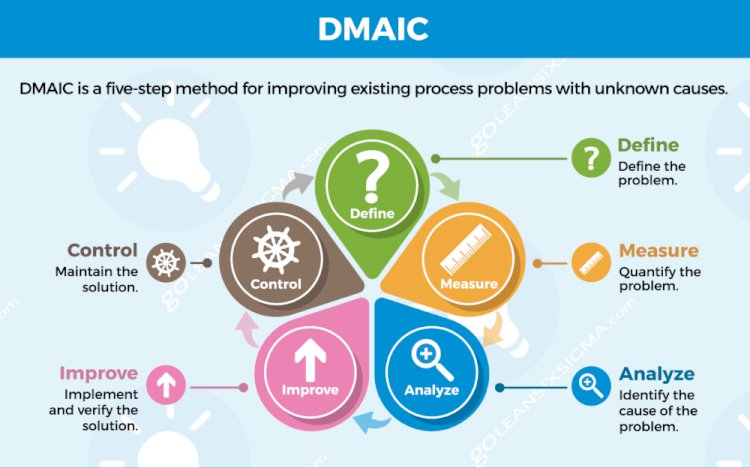

In the Improve phase of the Six Sigma project, a solution or set of solutions are designed for the problem being faced in the process. The Analyze stage had given us the list of factors through statistical validation which were found to be impacting the project Y but How important Improve stage is in a Six Sigma project? The solutions designed in the Improve stage are targeted at these x’s which are impacting the project y.

Screening of Final x’s

First of all, all the x’s which are impacting the project y should be screened to have an idea about what kind of factors these are.

Designing of Solutions

Solutions are designed for the final x’s to eliminate the problem from the process. Various kinds of methods are used for designing solutions, with the most commonly being used QFD (Quality Function Deployment). QFD is done to identify the customer requirements and convert it into characteristics which can be numerically measured. These requirements are generated through various ways such as brainstorming, benchmarking with competitors, customer inputs, etc.

Risk Assessment

The designed solutions are analyzed and their risks are assessed through FMEA (Failure Modes and Effects Analysis). FMEA is generally done in a joint session by the project team. In this, various risks associated with the process and the possible solutions for the problem are thoroughly checked to find possible modes in which they can fail. Numerical ratings are given for these failure modes and their most likely impact on the process. Then present controls are listed for these failure modes and it is concurred whether these controls are enough to check them. The frequency of the occurrence of these failure modes is also listed.

Once, all the failure modes have been listed along with their effects on the process, current controls and the frequency of occurrence, a RTP (Risk Treatment Plan) is designed to eliminate or reduce the identified failure modes for the possible solutions and the risks associated with them.

Screening of possible solutions

The identified solutions are screened on the basis of costs required, time duration needed, ease of implantation, potential benefits, etc. In case there is costs involved such as purchase of new equipment, process change, extensive training, etc then approval has to be sought from top management as it may not have been foreseen at the beginning of the project. Change management techniques are the most used in Improve phase due to dependence upon the others for implementation of the solutions.

Action Plan

An Action Plan should be prepared about how the identified solutions will be implemented and what will be the time duration for this.

Pilot Project

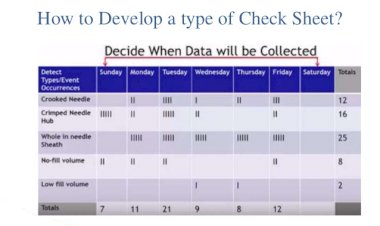

The identified solutions to be implemented should be done in a limited part of the process through a pilot project. Once a fixed period has passed and implemented solutions have started showing results, then data for the pilot project should be collect to validate whether the project has improved to the desired level or not. Once it has been statistically validated that process has improved, then it is time to implement the solutions in the entire process.

Shishu Pal

Shishu Pal

Comments (0)

Facebook Comments